-

Welcome

click meConsulting -

Consultation:

021-5195 0828

Service:

021-5195 0828 -

In the new century, water has become strategic resource. Nowadays water resource has become more and more uptight, simply treat wastewater and discharge has been increasingly unable to meet the strategic needs of development of enterprises and the country. Treat the wastewater and then reuse is the only way to sustainable development.

Forenv has become the industry's pedestrian and leader in water reuse project, and has international leading technology in the water reuse area.

1,MBR process reuse

Wastewater processed by MBR treatment can reduce its COD to less than 20mg / L and its SS less than 1mg / L. The processed water fully meet the national standard of reclaimed water and can be used in life miscellaneous water, factory/car washing water, circulating cooling water and other non-direct drinking water purposes.

After MBR, other deep treatment measures can be added, such as ultraviolet disinfection, chlorine and other equipment, to kill the harmful bacteria and other substances in the water, to further increase the security of reclaimed water.

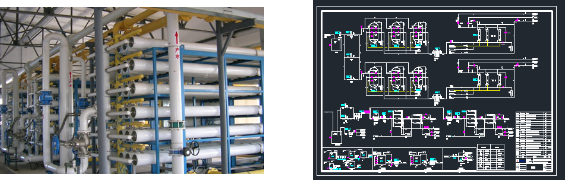

2,Double membrane method

Using the ultrafiltration/microfiltration membrane for pretreatment and reverse osmosis/nanofiltration membrane for advanced treatment, the electrical conductivity of the outcome water can decrease to less than 200us/cm and its bacteria, hardness and COD are close to zero. Water quality meets most of the requirements of industrial production, and is superior to the tap water quality in most areas.

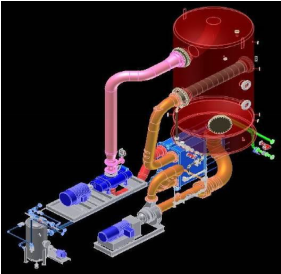

3,Low temperature evaporation and condensing crystallization

Forenv adopts international advanced evaporation technique: evaporate wastewater with relatively high concentration of ion or organic matter, directly reuse the evaporation condensation water, crystallize the residue on evaporation, recover useful minerals and salt, continue to deal with concentrated water produced in the process of other reclaimed water reuse methods, until wastewater zero discharge and 100% reuse is achieved.

A case study of water reuse project of a printing and dyeing factory in Shaoxing using double membrane method

Water quantity: 300m3/hr

Raw water: printing and dyeing wastewater after treatment

Raw water quality: COD250mg/L, Electrical conductivity 5000us/cm, Ammonia nitrogen 15mg/L, turbidity <10NTU

Water quality after treatment: COD<10mg/L, SS<1mg/L, Electrical conductivity <500us/cm

Treatment process: double membrane method

Scene photos

Back to top

Consultation

021-51950828